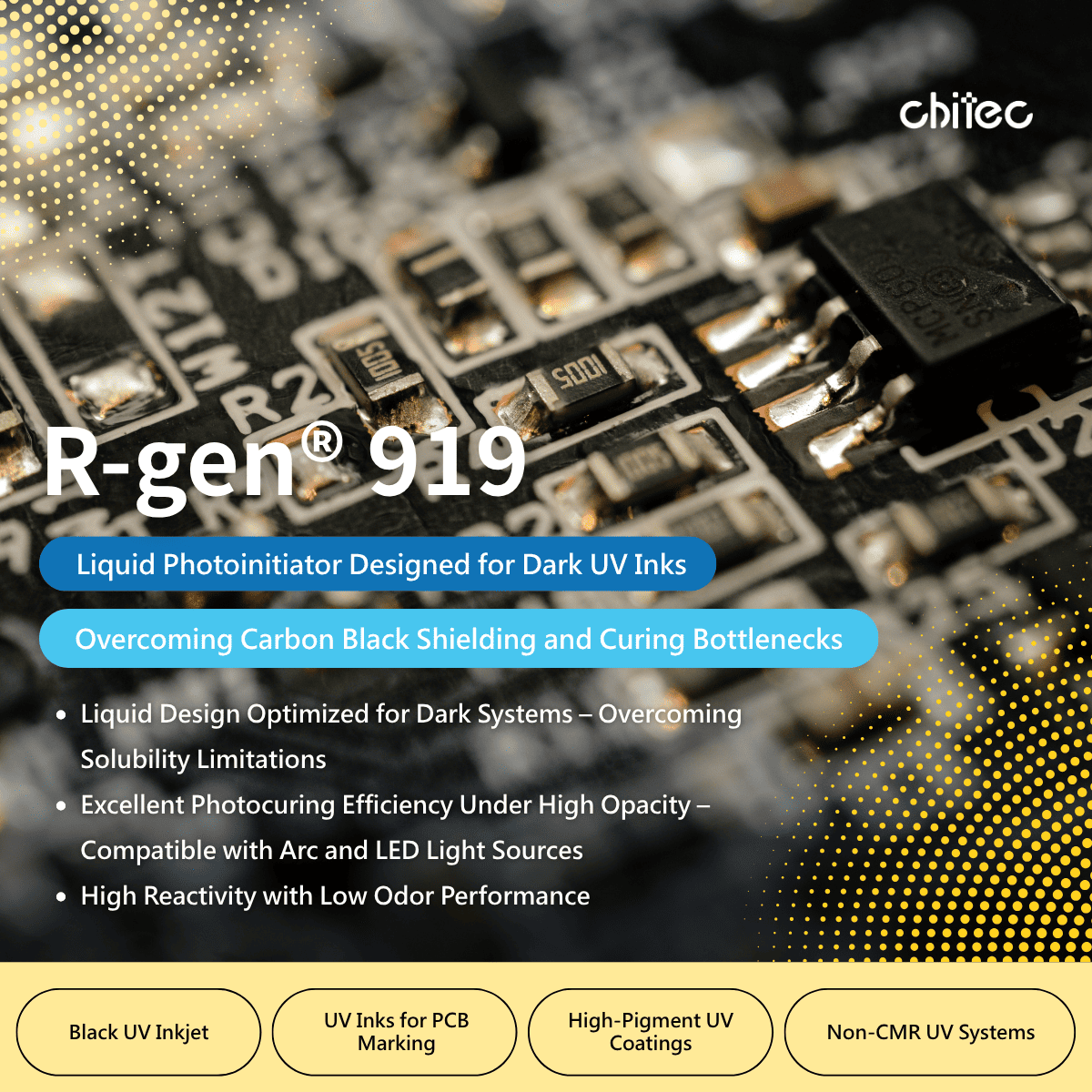

R-gen® 919: Liquid Photoinitiator for Dark UV Inks | Overcoming Carbon Black Shielding & Curing Bottlenecks

In industrial inkjet printing, electronic marking, and premium packaging applications, achieving “deep and uniform black” in UV inks and coatings is a key quality requirement. However, excessive carbon black leads to poor light penetration, incomplete curing, surface tackiness, and adhesive residue, posing significant challenges to production yield and product quality.

Chitec’s R-gen® 919 liquid photoinitiator is specially engineered for dark and high-filler UV systems. Even under highly opaque carbon black conditions, it maintains outstanding UV-curing efficiency, effectively resolving the long-standing curing bottleneck faced by the industry.

Three Breakthrough Highlights to Overcome Dark Formulation Challenges

1. Fully Liquid Design – Solving Solubility Limitations of Traditional Photoinitiators

R-gen® 919 is fully miscible with most acrylic resins. Even in high-pigment, high-opacity formulations, it remains evenly dispersed, preventing sedimentation and printhead clogging issues.

2. Compatible with Arc and LED Light Sources – Curing Speed up to 10–20 m/min

R-gen® 919 initiates polymerization rapidly even in dark UV inks, making it ideal for high-speed PCB inkjet printing, precision electronic component marking, and high-efficiency automated production lines.

3. High Curing Efficiency with Virtually No Odor – Compliant with Global Regulations

R-gen® 919 contains no CMR 1(b) substances, making it suitable for high-safety markets and odor-sensitive applications.

Key Application Areas

-

Black UV Inkjet

-

UV Inks for PCB Marking

-

High-Pigment UV Coatings

-

Non-CMR UV Systems

👉 View Full Technical Article 📧 Contact Us for Samples & Consultation