Chiguard® 380W Optical-Grade UV Absorber|UV Solution Designed for Optical Films and Food-Grade PET

In the market of plastic products striving for high transparency, weather resistance, and sustainable recyclability, the choice of a UV absorber has become a key indicator for product differentiation and entry into high-end applications.

Developed by Chitec Technology, Chiguard® 380W is an optical-grade UV absorber featuring high extinction efficiency, low color contribution, and excellent thermal stability. Its unique optical and thermal stability performance makes it especially suitable for applications highly sensitive to transparency and appearance, such as PET films, bottles, and optical films.

Chiguard® 380W not only provides superior UV shielding and color stability but has also passed multiple international regulatory certifications (FDA, REACH, etc.), establishing a solid technical foundation for simplified formulation and stable processing. From food packaging and transparent beverage containers to optical materials, Chiguard® 380W is an ideal choice for companies pursuing efficient, sustainable, and reliable formulation design.

Five Key Technical Advantages and Application Values of Chiguard® 380W

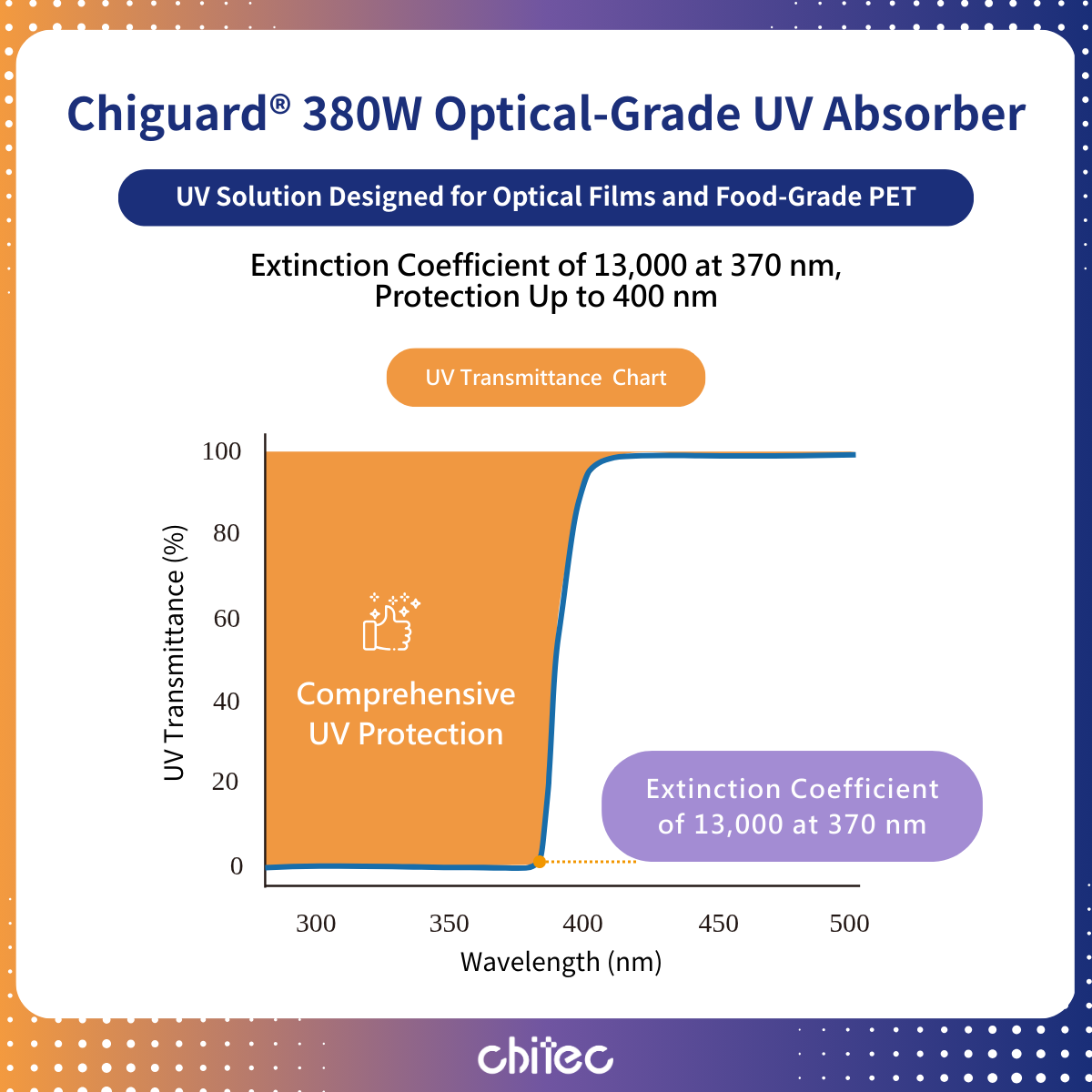

High-Efficiency UV Shielding | Extinction Coefficient of 13,000 at 370 nm, Protection Up to 400 nm

Chiguard® 380W has a broad UV absorption capability, covering UV-C, UV-B, and extending to UV-A up to 380 nm. By increasing the dosage, it can further enhance shielding up to 400 nm, delivering almost complete UV protection.

At 370 nm (the UV-B and UV-A junction), its extinction coefficient reaches 13,000, allowing effective absorption of a large amount of UV energy even at low dosage. This ensures exceptional UV shielding efficiency and stability, providing an ideal solution for dual demands of high transparency and strong UV protection.

For PET films, transparent packaging containers, and optical materials, Chiguard® 380W achieves the same UV blocking performance at lower dosages, effectively reducing haze and yellowing risks.

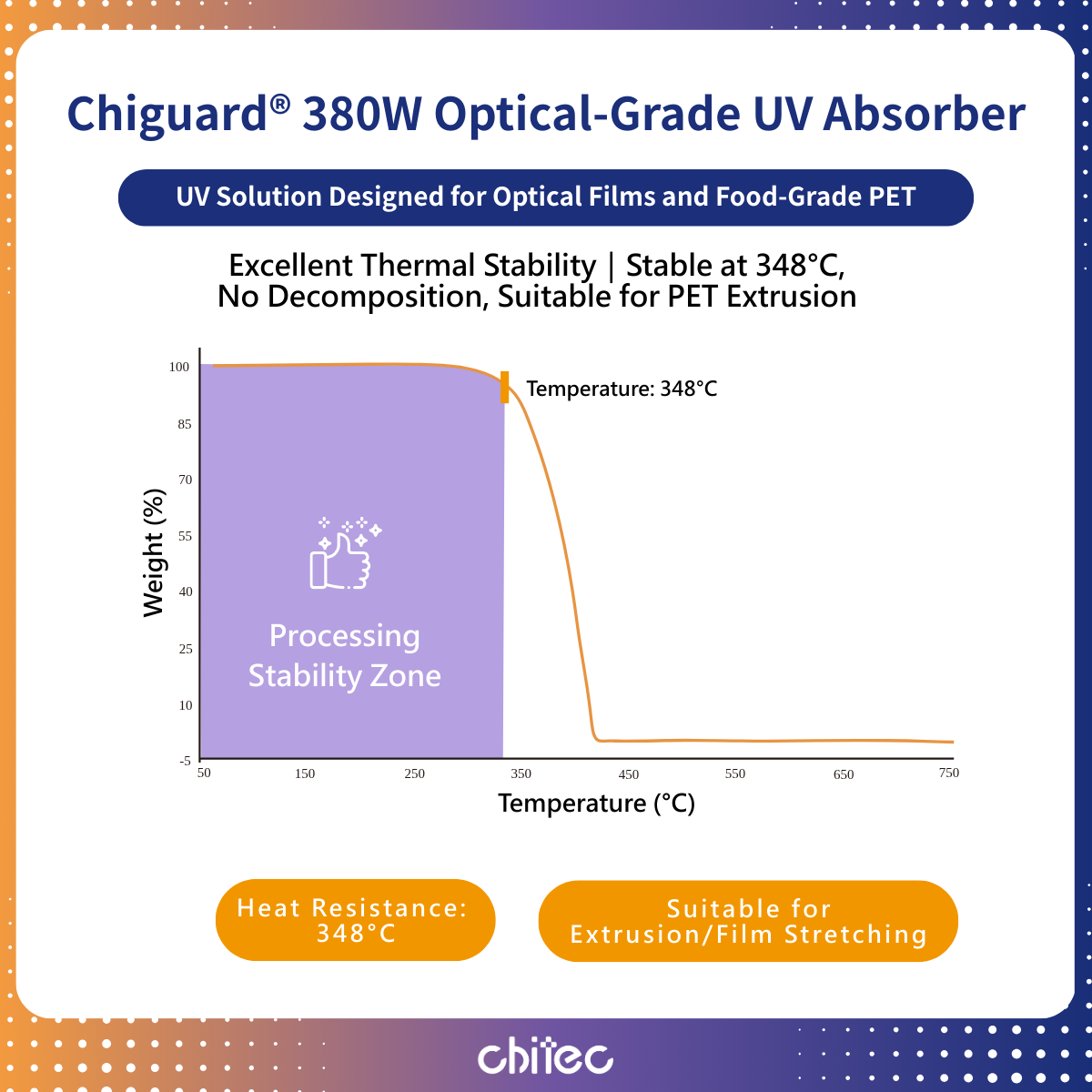

Excellent Thermal Stability | Stable at 348°C, Suitable for PET Extrusion

Thermogravimetric Analysis (TGA) tests under the following conditions—starting at 60°C, heating at 20°C/min to 800°C, and holding for 5 minutes—show that the “10% weight loss temperature” averages 348.83°C.

This demonstrates excellent thermal stability, making Chiguard® 380W particularly suitable for high-temperature, short-cycle processes such as PET extrusion, melt molding, and film stretching. Even in high-heat environments, it maintains stable physical and optical performance, ensuring consistent quality and product reliability.

Ultra-Low Initial Color & Non-Staining | Ideal for Optical Films

Tests show that the Yellow Index (YI) of Chiguard® 380W powder is only -3 to -4. Its non-staining characteristic has made it a preferred choice for optical-grade applications.

This means Chiguard® 380W barely affects the transparency or color of end products, making it especially suitable for optical film materials.

Processing Stability & High Compatibility | Improved Dispersion and Yield

Chiguard® 380W has high compatibility with PET resins and maintains uniform dispersion even at high loadings, with low migration tendency. It preserves transparency over time without affecting melt flow, and is characterized by excellent melt stability, no odor, no yellowing, and no deposits.

It is therefore an ideal choice for high-end transparent applications that require both processing stability and quality assurance.

Certified by Multiple International Regulations

• U.S. FDA Food Contact Certification (FCS #935)

• EU REACH Registration (10–100 t/y)

• EU EFSA Approval

• China GB Standards Compliance

• Japan Food Contact Regulation

• South America MERCOSUR Certification

Versatile Application Scenarios

- Film/Sheet/Plate for Engineering Plastics

- Window Films

- Optical Lenses

- LCD Displays

- PET Bottles and Containers

- Food-Contact Films (Food Packaging)

Contact Us: sales@chitec.com

建議您使用以下瀏覽器觀看本網站,

要下載瀏覽器,請直接點擊以下:以獲得最佳瀏覽效果。