During the continuous evolution of UV curing technology, formulators consistently face three major challenges: yellowing, surface uncured layers, and residual odors. These issues are particularly evident in clear coatings and light-colored inks, not only affecting product appearance but also testing a brand's commitment to quality and sustainability.

Chivacure® P-4075 is a key innovation born specifically to solve these pain points.

It is a liquid photoinitiator blend designed for low-migration printing inks pursuing exceptional appearance. Through proprietary ratios and eco-friendly manufacturing, it redefines UV curing standards.

Technical Breakthroughs & Advantages

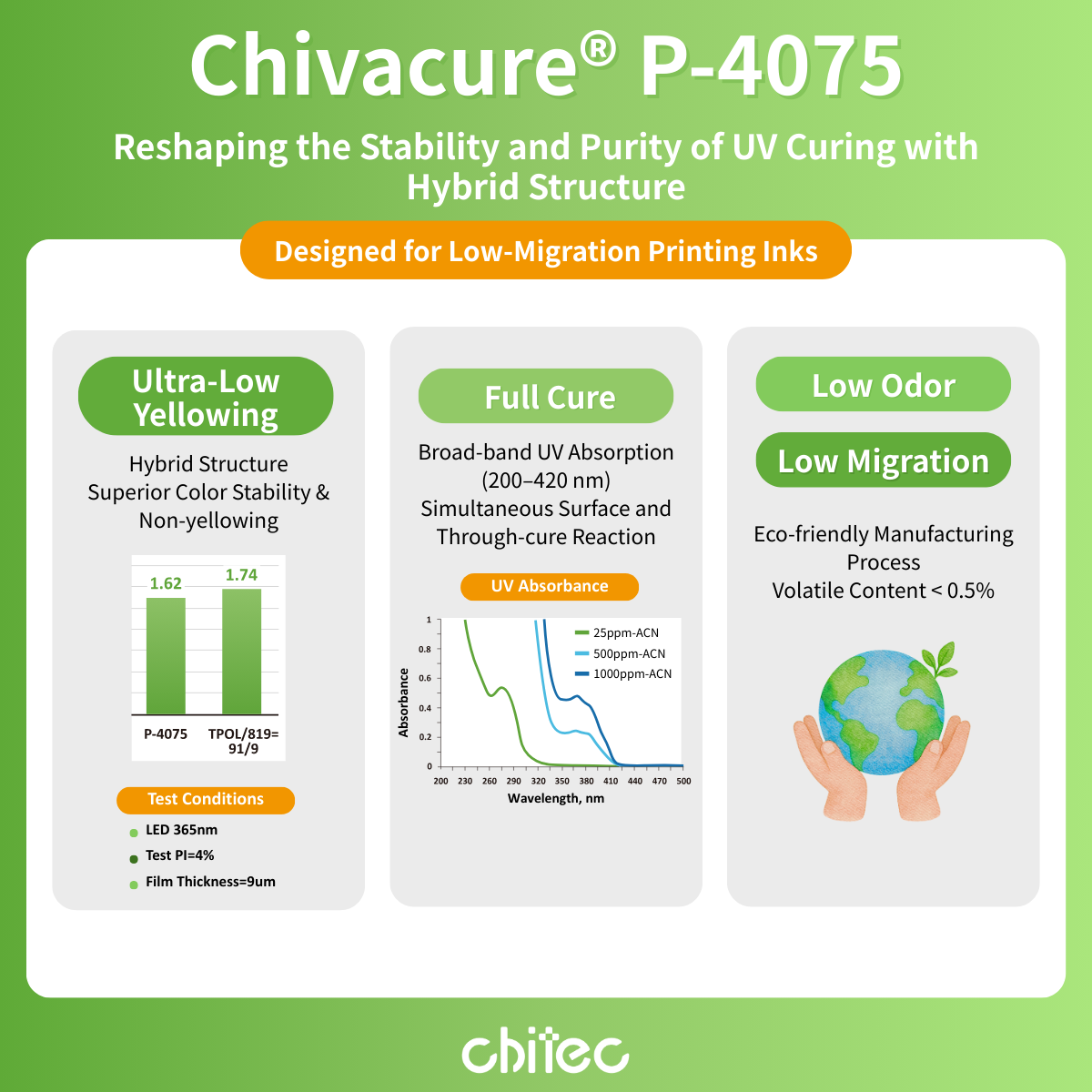

Pain Point 1: Yellowing & Insufficient Color Stability

Under high-energy UV or high-temperature conditions, traditional photoinitiators easily produce side reactions leading to color shifts and yellowing. Pale yellowing in clear coatings and graying in white inks have long been concerns for ink and coating manufacturers.

P-4075 utilizes a dual-effect hybrid structure of Oligomeric Hydroxyketone and Phosphine Oxide, combining stability with high reactivity:

- Disperses energy absorption to reduce radical aggregation and thermal reactions, inhibiting yellowing.

- Dual-functional radical generation allows surface and deep curing to proceed simultaneously.

- The polymeric chain stabilized structure effectively prevents thermal degradation and reduces odor.

Pain Point 2: Incomplete LED Curing & Surface Tackiness

LED curing has become the industry mainstream. However, because its wavelength is concentrated at 365–405 nm, many traditional photoinitiators have insufficient absorption in this range, causing incomplete curing or surface tackiness.

P-4075 possesses a broad absorption structure (200–420 nm), corresponding to UVA, UVB, and UVC sources simultaneously.

- Hydroxyketone Structure: Instantly generates radicals upon light absorption to rapidly initiate surface polymerization, shortening drying time and eliminating tackiness.

- Phosphine Oxide Structure: Strong absorption for long-wavelength light (especially above 365 nm), enabling energy to penetrate deep into the coating to ensure full cross-linking.

● Uniform deep curing, avoiding inner softening or insufficient adhesion.

● Highly compatible with TMPTA and various acrylic systems.

Pain Point 3: Environmental & Regulatory Challenges

Modern formulations must simultaneously consider performance, sustainability, and user experience. Traditional photoinitiators often impact production environments and end-product odor due to high volatility and strong scents.

P-4075 utilizes Chitec's proprietary eco-friendly process, using no harmful solvents throughout the entire production.

● Water solubility < 0.1 g / 100 ml

● Liquid stability, transparent, and ultra-low odor.

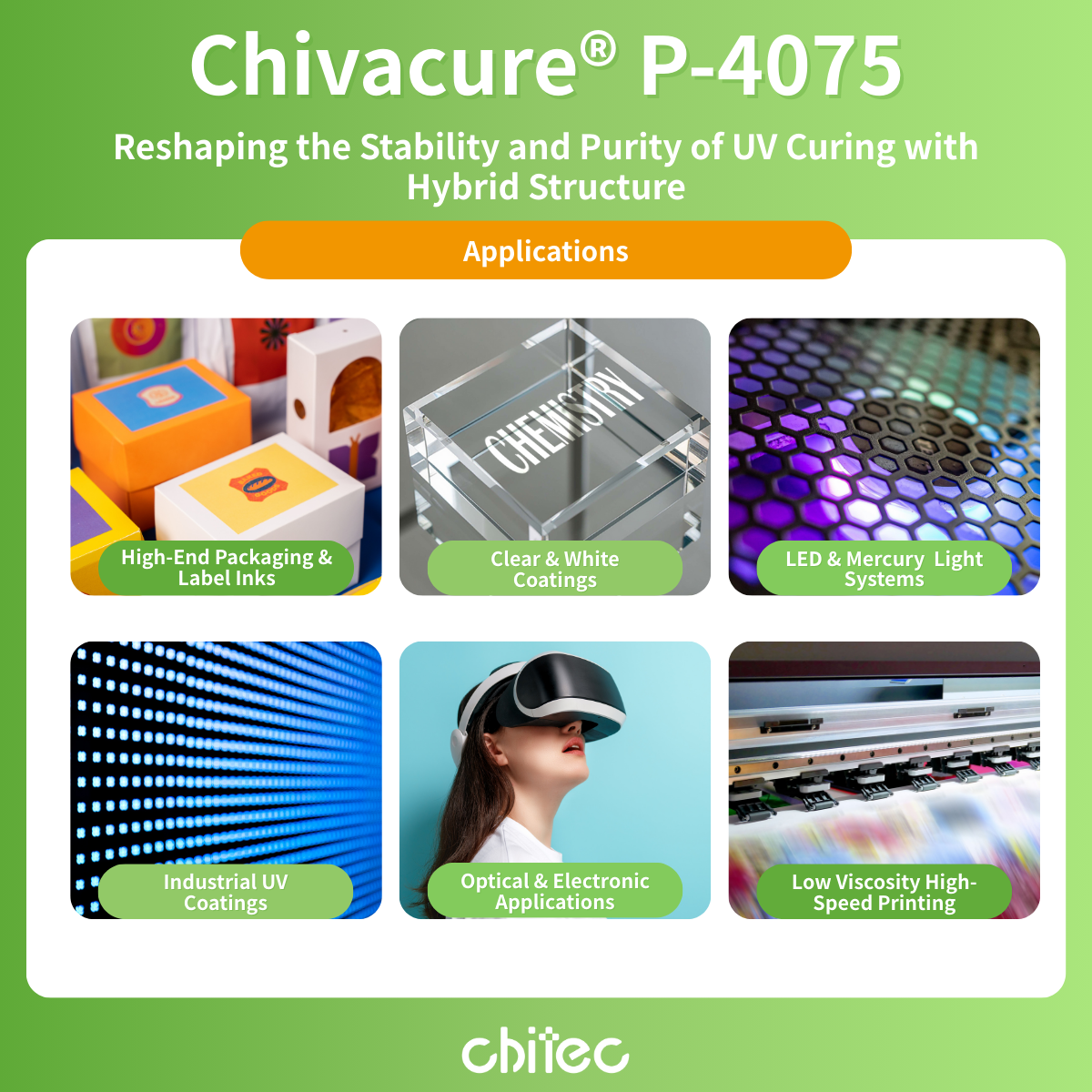

Six Core Application Scenarios

1. High-End Packaging & Label Inks

Low odor and low migration, suitable for odor-sensitive non-food consumer packaging. Compatible with Flexo, Offset, and Gravure systems.

Application Scenarios: Cosmetic boxes, luxury gift sets, label printing.

2. Clear & White Coatings

Suitable for UV varnishes and white coatings. Ideal for yellowing-sensitive applications such as PET protective films and electronic housings.

Representative Applications: Optical films, PET packaging, 3C electronic coatings, high-gloss clear coats.

3. LED & Mercury Light Systems

Broad absorption range (200–420 nm). Suitable for transition applications requiring compatibility with both Mercury lamps and LED.

Representative Applications: Printing inks, UV varnishes, UV adhesives, spray coatings.

4. Industrial UV Coatings

Used for wood finishing, plastic parts, and metal protective paints. Balances fast curing with mechanical performance (adhesion, hardness).

Representative Applications: UV floor coatings, furniture protection layers, electronic component protection films.

5. Optical & Electronic Applications

Suitable for optical applications highly sensitive to color, transparency, and odor. Common in display optical films and lens coatings.

Representative Applications: AR optical films, MR/VR lens protection layers, smartphone lens coatings.

6. Low Viscosity High-Speed Printing

Suitable for roll-to-roll, production digital printing, and UV inkjet systems. Balances low viscosity and high flow with rapid response.

Representative Applications: UV inkjet inks, digital printing inks, flexible packaging printing.