Chiguard® R-455: World's First Polymer-Integrated UV Absorber

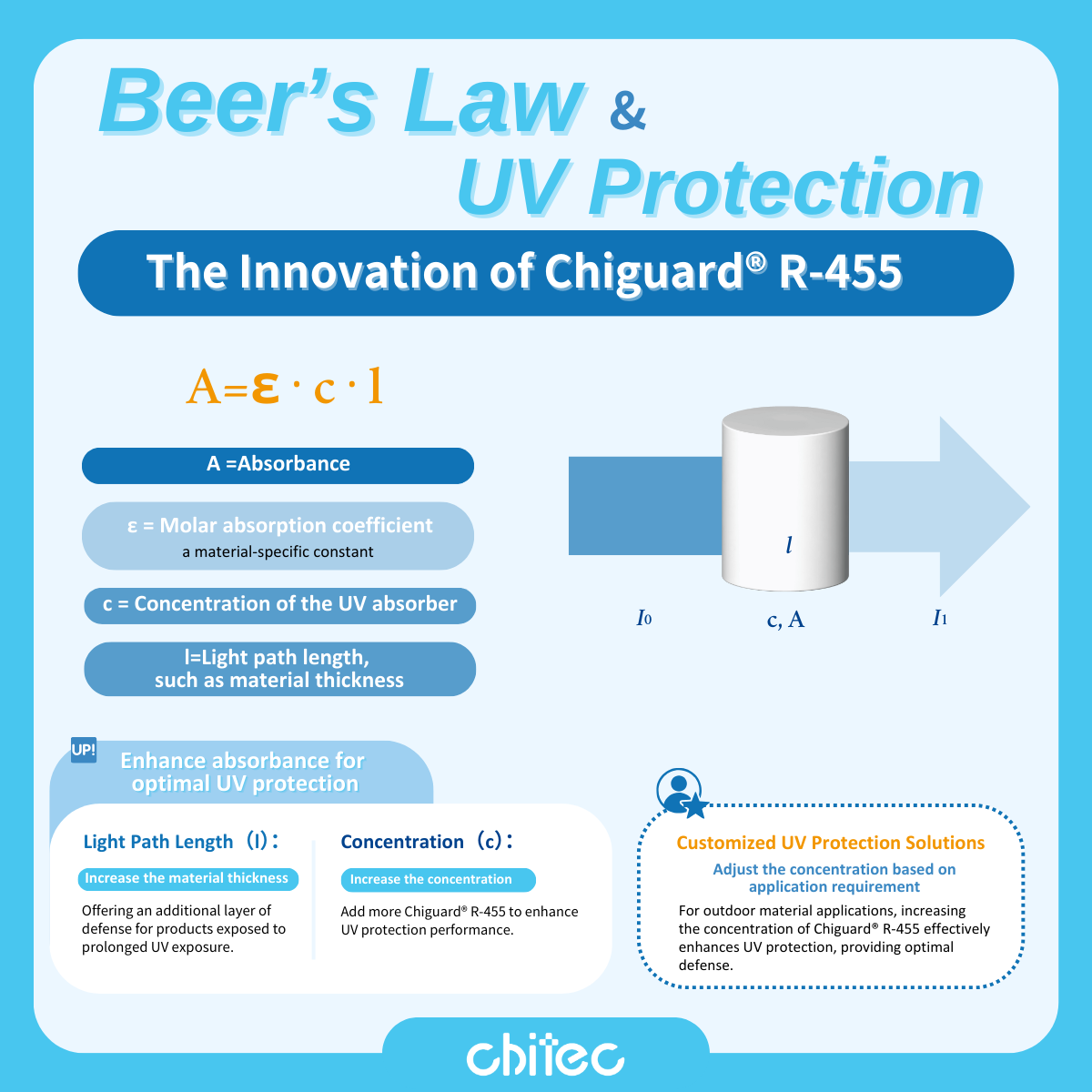

Beer’s Law and UV Protection: The Innovation of Chiguard® R-455

Why is Chiguard® R-455 a superior choice for UV protection materials? The answer lies in the application of Beer’s Law—a key principle for precise UV coating design.

Optimizing UV Protection with Beer’s Law: Beer’s Law defines the relationship between light absorption, material concentration, and light path length. This allows formulators to design UV-resistant coatings with predictable performance.

The formula: A = ϵ · c · l

- A: Absorbance – the amount of light absorbed by the material.

- ϵ: Molar absorption coefficient – a material-specific constant.

- c: Concentration of the UV absorber.

- l: Light path length, such as material thickness.

Key Parameters to Control:

- Concentration (c): Adjusting the concentration of Chiguard® R-455 enhances or reduces UV protection. Higher concentrations provide stronger absorption, ideal for outdoor or high-exposure applications.

- Light Path Length (l): Increasing the material thickness extends light path length, strengthening UV defense for long-term exposure conditions.

Unique Advantages of Chiguard® R-455

R-455 has been proven to participate in polymer chain extension reactions, allowing short-chain molecules to chemically link into long-chain polymers. This process enhances material strength, stability, and molecular integrity — widely applied in high-performance materials like reinforced plastics and advanced polymers.

Unlike conventional UV absorbers, R-455 can chemically embed into the polymer backbone, creating durable, non-migrating UV protection. This innovation transforms R-455 from a mere additive into a structural component, setting a new benchmark in UV absorber technology.

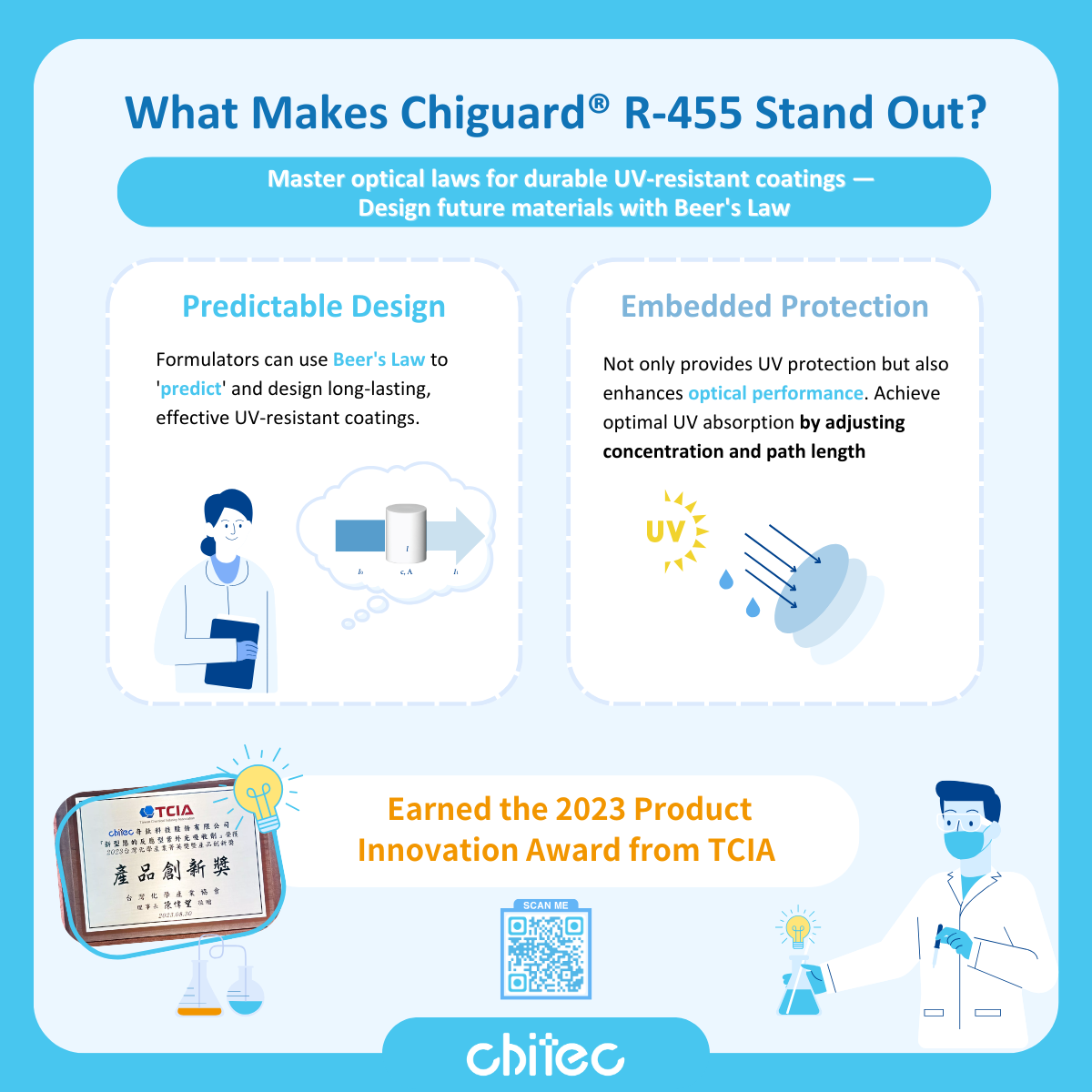

- Predictive Design: Formulators can design long-lasting UV protection by applying Beer’s Law in material formulation.

- Enhanced Functionality: Beyond basic protection, R-455 improves optical and stability properties by optimizing absorber concentration and light path length.

- Industry Recognition: R-455 was awarded the 2023 Taiwan Chemical Industry Association (TCIA) Product Innovation Award, recognizing its breakthrough chemistry and market impact.

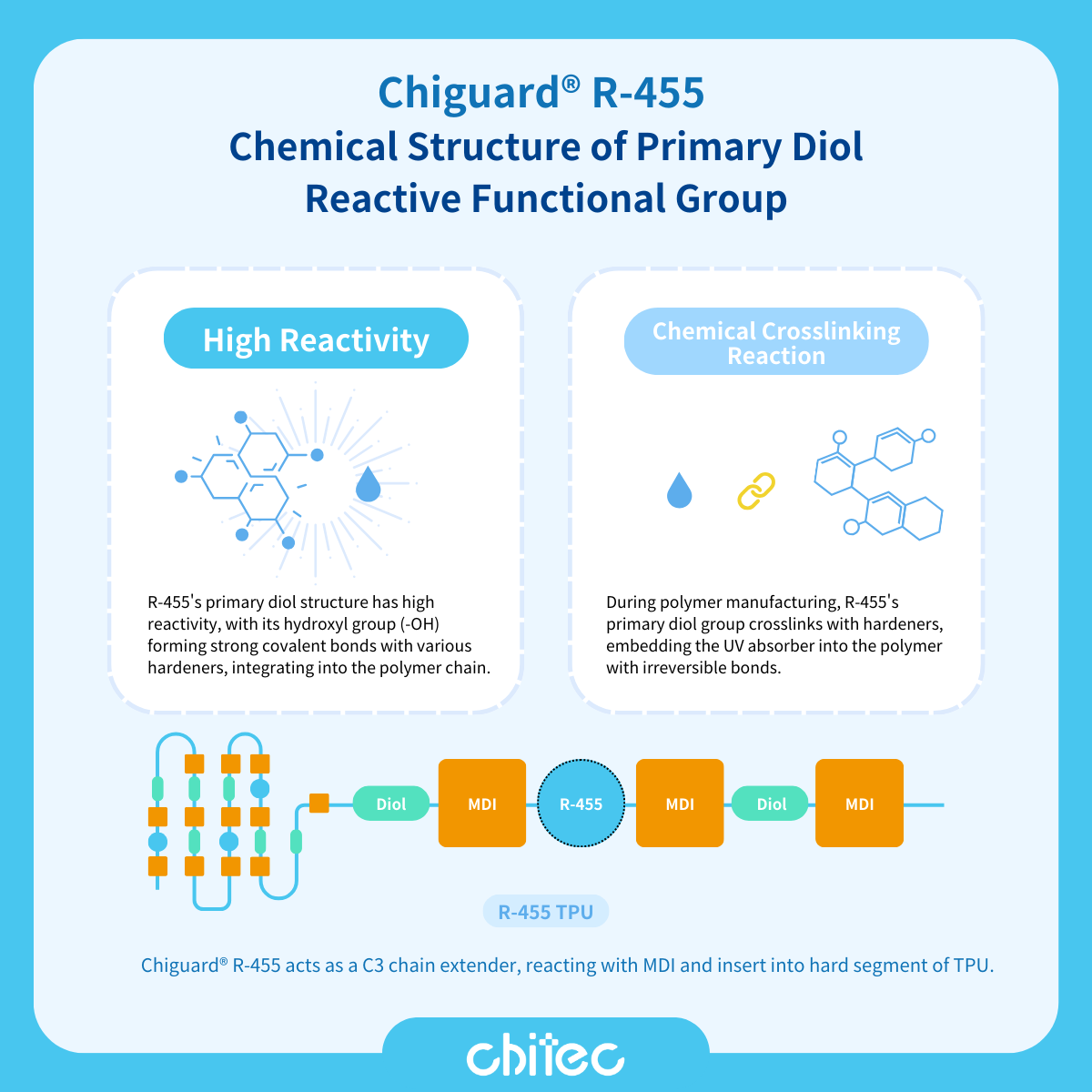

Molecular Structure and Features

Chiguard® R-455 is a reactive benzotriazole-type UV absorber developed by Chitec Technology, designed specifically for polyurethane applications requiring superior UV protection. R-455 features a primary diol structure that reacts with curing agents such as isocyanates, melamine resins, or siloxanes to form covalent bonds within the polymer backbone, ensuring long-lasting UV resistance.

- High Reactivity: The primary diol group (–OH) in R-455 exhibits strong chemical reactivity, allowing it to bond with multiple hardeners to form covalent linkages, becoming part of the polymer matrix.

- Chemical Crosslinking: During polymer formation, R-455 reacts with curing agents through crosslinking, embedding the UV absorber permanently within the polymer structure and preventing loss or degradation.

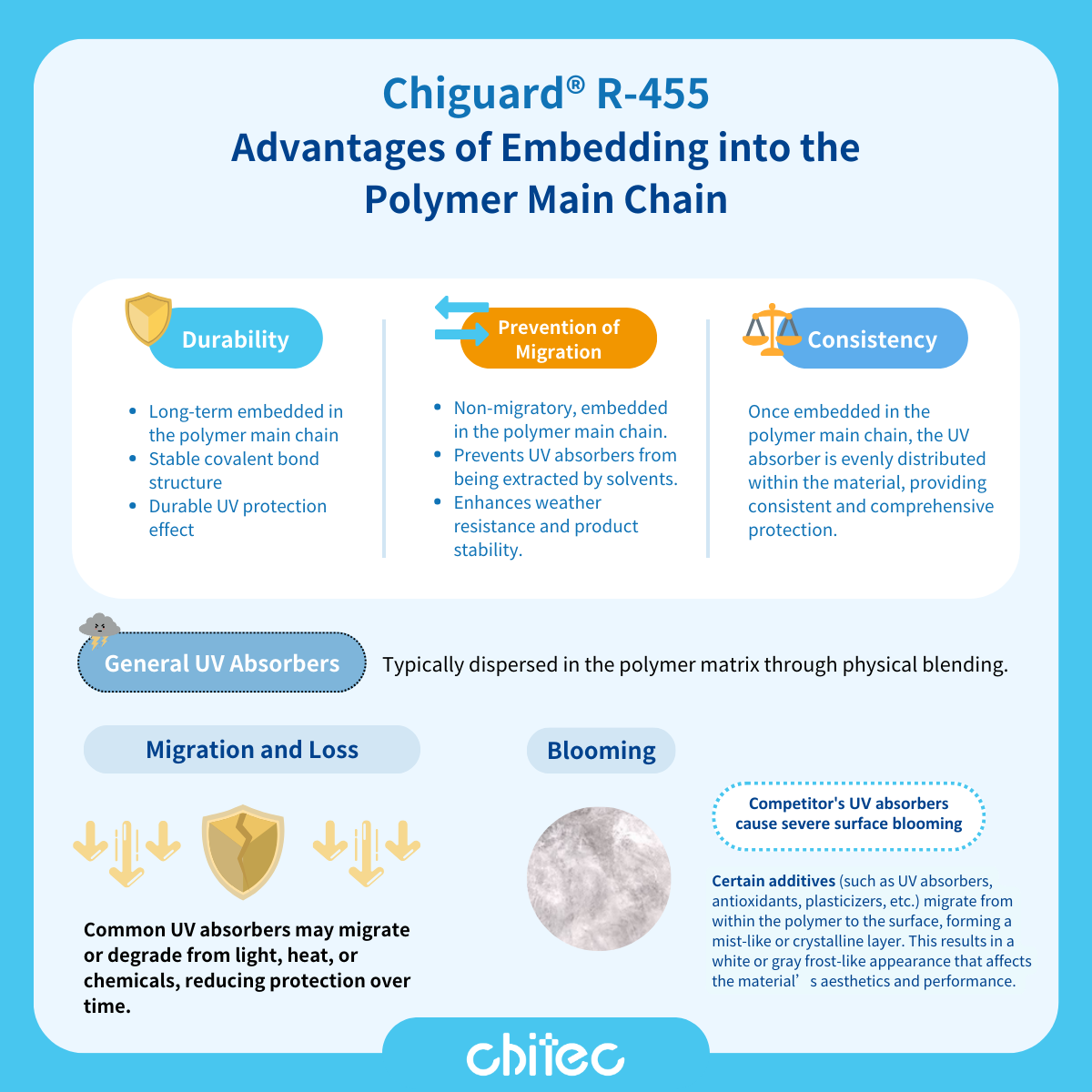

Advantages of Embedding into the Polymer Backbone

- Durability: Covalent bonding provides superior structural stability, ensuring long-term UV protection that doesn’t deteriorate over time.

- Anti-Migration: Because R-455 is part of the polymer chain, it eliminates migration and extraction issues found in traditional additives, maintaining clarity and performance.

- Consistency: The embedded structure ensures uniform UV absorption across the material, delivering balanced and reliable protection.

Comparison with Conventional UV Absorbers

Most conventional UV absorbers rely on physical dispersion within polymer matrices, which often leads to several drawbacks:

- Migration and Loss: Over time, these absorbers can migrate, decompose, or evaporate under heat and light exposure, reducing UV protection efficiency.

- Blooming (Frosting): Physically mixed UV absorbers can migrate to the surface, forming a hazy or crystalline layer known as blooming. This not only affects optical clarity but also diminishes material aesthetics and performance consistency.

Chiguard® R-455 solves these problems by forming permanent chemical bonds, maintaining UV stability, transparency, and structural integrity even under severe conditions.

Experience the Future of UV Protection

Chiguard® R-455 represents a revolutionary step forward in UV absorber technology — combining chemistry, stability, and performance for the next generation of advanced coatings and polymers.

📨 For technical details or sample requests, please contact:

sales@chitec.com