📘 “Six Causes of Plastic Yellowing”

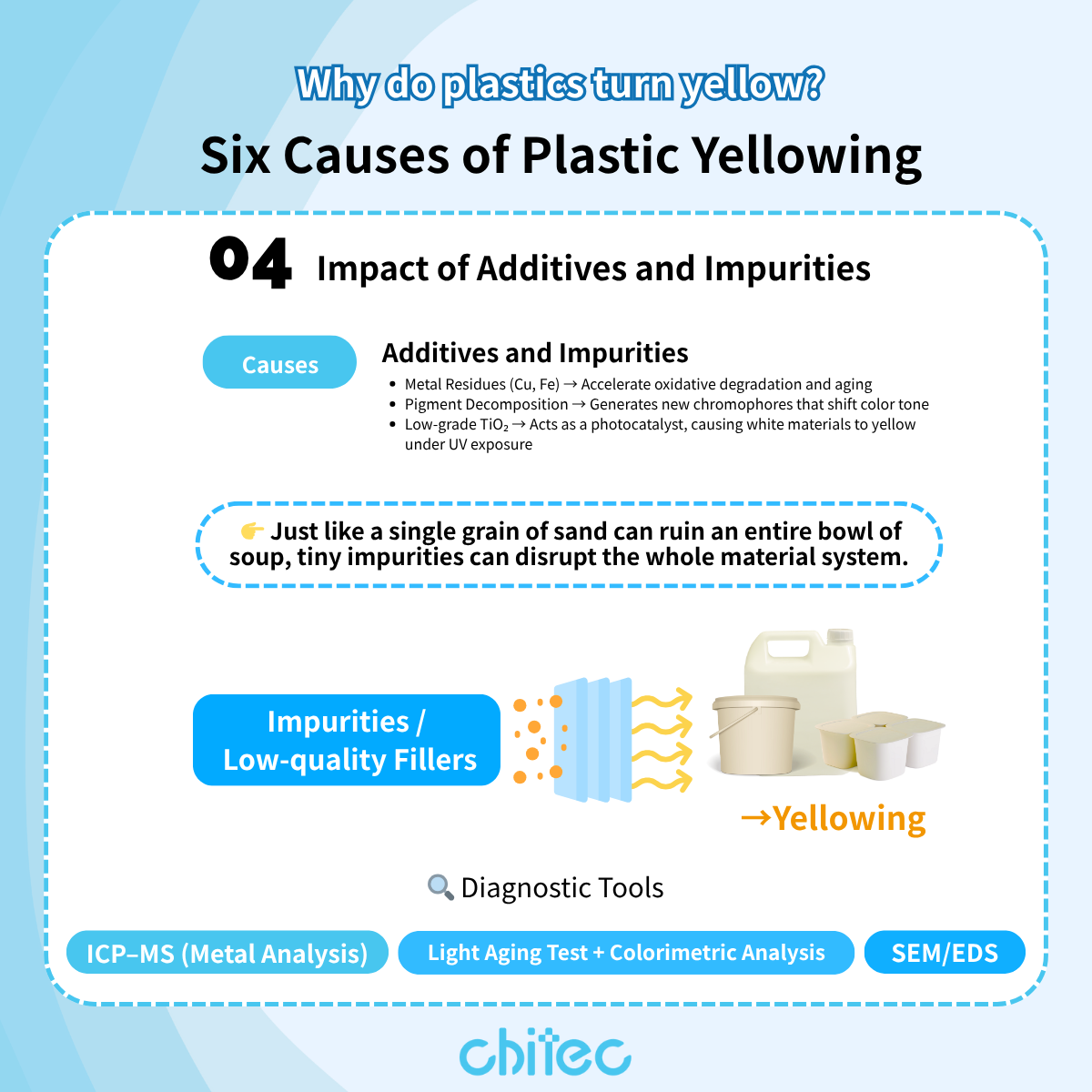

Part 4: Additives and Impurities

Phenomenon: Consistent Formulation, Yet Different Colors

Even when the formulation and processing conditions are identical, different batches of plastics may still show color variation—some remain bright white, while others turn slightly yellow. This often leads to assumptions about “processing issues,” but the real cause is often hidden in small, easily overlooked factors: additives and impurities.

Core Mechanisms: Small Factors, Big Impact

• Metal Ion Residues

Residual metal ions such as copper or iron in polymerization or processing can act as catalysts and accelerate the decomposition of peroxides. This essentially steps on the gas pedal of the aging reaction, causing plastics to yellow faster.

• Pigment Decomposition

Certain pigments break down when exposed to light, releasing new chromophores that absorb visible light. This not only alters the original color but may cause noticeable shifts—such as white turning yellow or red becoming darker.

• Titanium Dioxide Quality Differences

Titanium dioxide (TiO₂) is widely used as a white pigment. However, anatase-type or poorly coated grades may act as photocatalysts under UV exposure, accelerating polymer degradation and promoting yellowing. In contrast, rutile-type TiO₂ with proper surface treatment offers much better resistance to discoloration.

Common Materials & Scenarios

• White appliance housings (PP, ABS): Poor-quality TiO₂ may cause bright white parts to turn yellow quickly.

• Colored plastic parts (PE, PVC): Pigments with poor lightfastness may shift color after sun exposure.

• Recycled or blended materials: High metal impurity levels increase the likelihood of discoloration during processing or service.

🔍 Testing: How to Identify the Root Cause?

- ICP-MS (Metal Element Analysis): Detects trace metal residues such as Cu and Fe to determine catalytic impurities.

- Light Aging + Color Difference Testing: Significant color deviation between batches after UV exposure often points to pigment or TiO₂ quality issues.

- SEM/EDS: Observes the dispersion of pigments and fillers, and detects elements that may promote degradation.

👉 Summary: Plastic yellowing is not always the result of light or heat alone—sometimes it comes from tiny internal flaws. This is why strict control over raw material purity and additive quality is essential.

📘 There are still 2 more articles in this “Plastic Aging Mechanism” series, helping you fully understand the chemistry behind yellowing, embrittlement, and gloss loss.

Read more –

Six Causes of Plastic Yellowing Part 1: Photo-oxidation

Six Causes of Plastic Yellowing Part 2: Thermal Oxidation

Six Causes of Plastic Yellowing Part 3: The “Side Effect” of Antioxidants

The Science of Stability: How UV Absorbers Extend Material Performance

🔹Chitec Technology | The Expert in Anti-Aging Solutions for Materials

建議您使用以下瀏覽器觀看本網站,

要下載瀏覽器,請直接點擊以下:以獲得最佳瀏覽效果。