Revonox® U-5068L — Advanced Thermal Stabilizer for High-Performance TPU

Excellent initial color, strong resistance to thermal yellowing, superb MFI control across reprocessing, while maintaining TPU’s good hydrolytic resistance and reducing crystalline points.

The Key to Exceptional TPU Product Quality

Initial Color: The Primary Factor of Product Appearance

In the application of thermoplastic polyurethane (TPU) materials, color is a crucial factor that influences consumer purchasing decisions. Bright colors not only attract attention but also symbolize product quality. The value of stable initial color lies in showcasing a pristine, new appearance for TPU products.

How Does Appearance Color Affect the Market?

With increasing market competition, consumer demands for products are becoming higher. Color is not only about aesthetics but also represents brand image and product quality. In high-end markets, such as automotive films and electronic product casings, consistent and long-lasting color stability is essential. Revonox® U-5068L (U-5068L) is a heat stabilizer specifically designed for TPU, ensuring that TPU products maintain color stability even after multiple thermal processes or in high-temperature environments.

Why Choose Revonox® U-5068L?

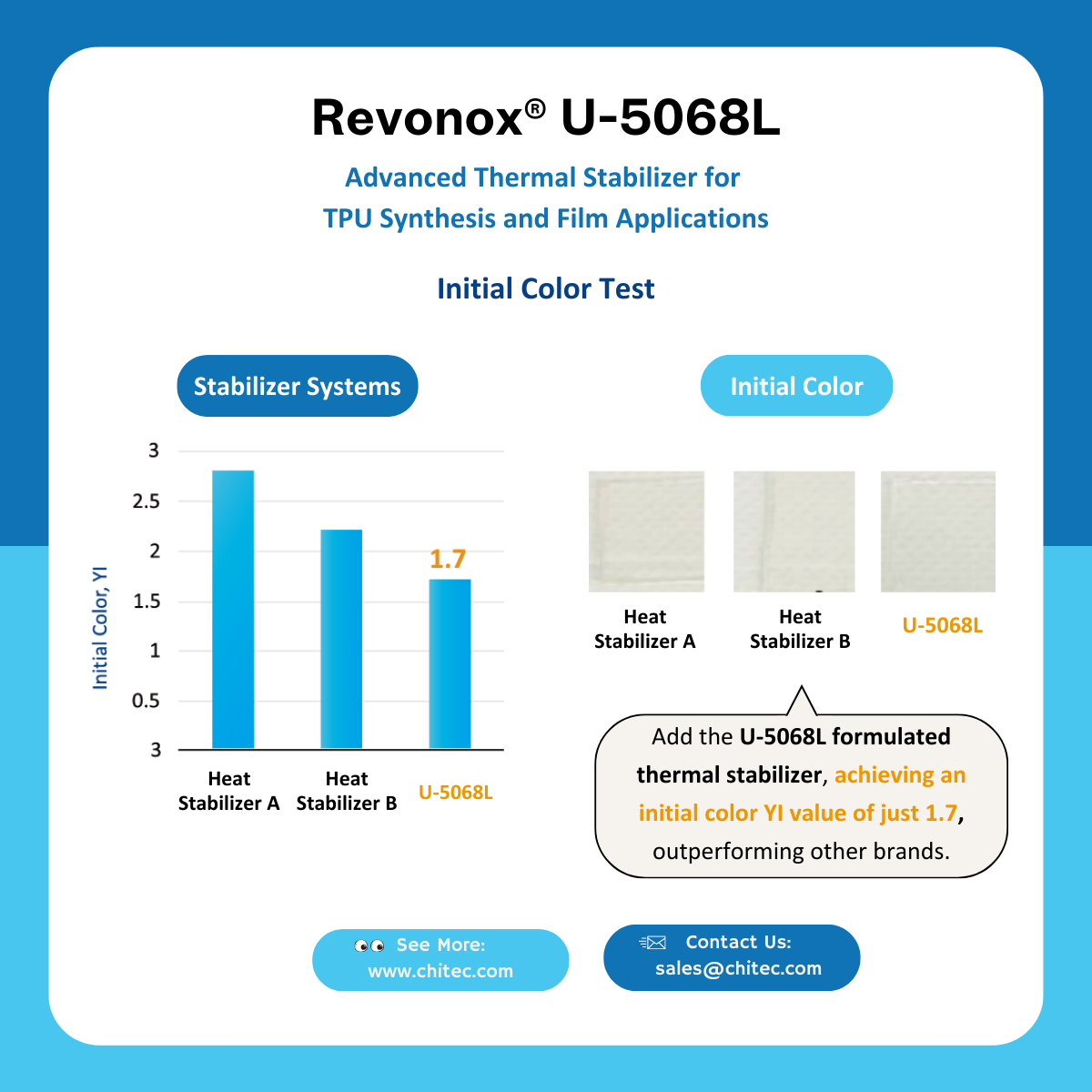

Initial Color Stability: U-5068L significantly inhibits yellowing (Yellow Index) during TPU synthesis, even in high-temperature environments of 200°C to 250°C required for twin-screw polyurethane synthesis, greatly reducing yellowing caused by reactions with moisture and oxygen.

- Heat Stabilizer A: Initial YI value of 2.8

- Heat Stabilizer B: Initial YI value of 2.2

- Revonox® U-5068L: Initial YI value of only 1.7

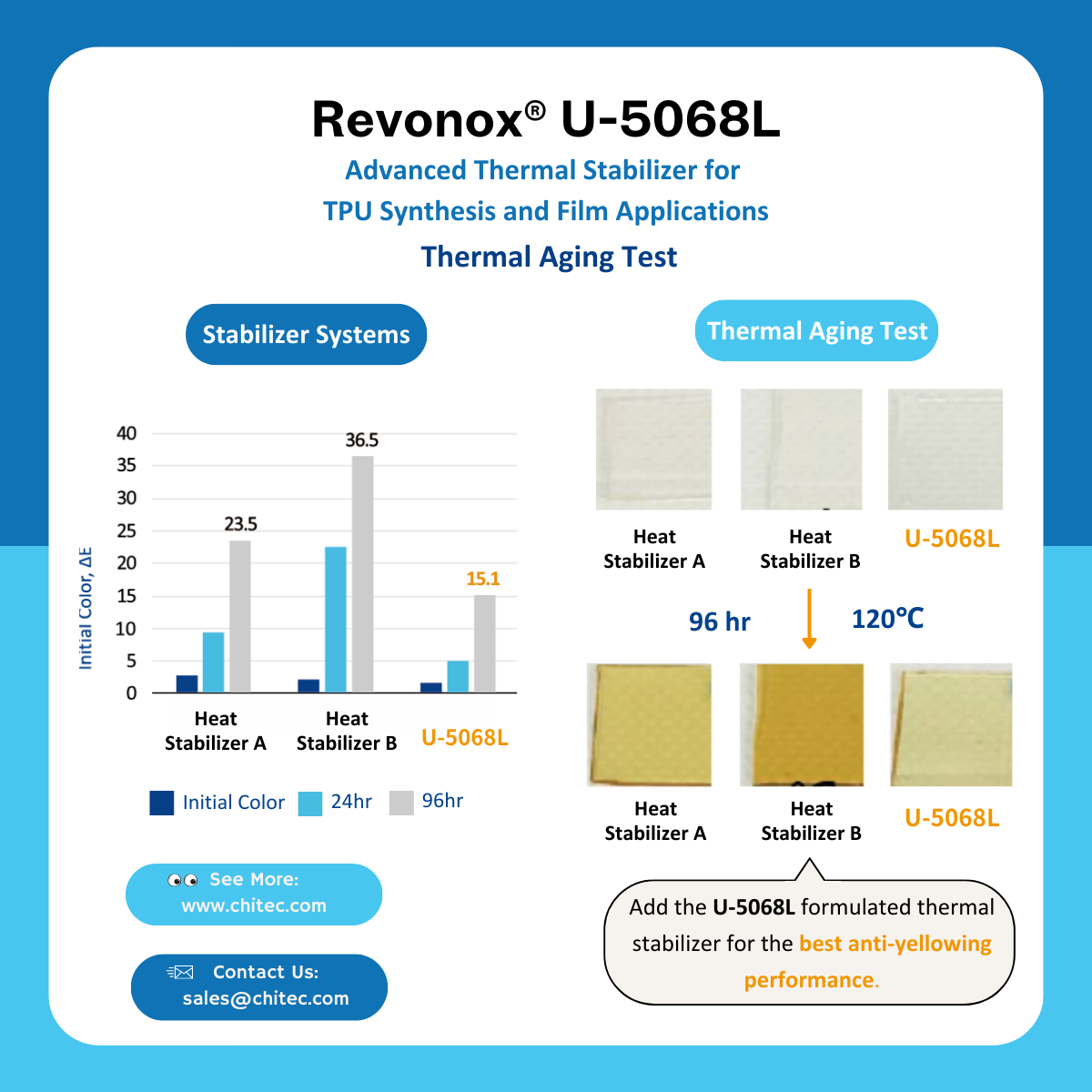

In a rigorous 120°C heat aging test for 96 hours, U-5068L exhibited the lowest ∆E. This indicates that U-5068L's performance in inhibiting thermal yellowing of TPU is significantly ahead of market competitors, maintaining the color stability of TPU materials even under harsh conditions.

Advantages of Choosing a Low Initial Color

- Enhance Product Appearance and Target High-End Markets: Providing TPU materials with low initial color and excellent thermal stability ensures that products remain aesthetically pleasing, meeting the stringent requirements of high-end application markets such as automotive films and electronic product casings.

- Increase Production Efficiency and Reduce Costs: By minimizing reprocessing and waste due to color issues, production costs are reduced, and efficiency and product competitiveness are improved.

Revolutionizing TPU Processing: Excellent MFI Control

A stable MFI is more than just a number; it’s a measure of molecular weight stability in polymers, directly influencing the physical properties of TPU. By incorporating Revonox® U-5068L during the synthesis phase, manufacturers can achieve unparalleled MFI control, empowering TPU to withstand the rigors of subsequent processing stages. This makes Revonox® U-5068L an indispensable heat stabilizer for high-performance TPU applications.

A stable MFI is more than just a number; it’s a measure of molecular weight stability in polymers, directly influencing the physical properties of TPU. By incorporating Revonox® U-5068L during the synthesis phase, manufacturers can achieve unparalleled MFI control, empowering TPU to withstand the rigors of subsequent processing stages. This makes Revonox® U-5068L an indispensable heat stabilizer for high-performance TPU applications.

As sustainability becomes a priority, edge-trim reclamation is increasingly common in TPU production. However, this eco-friendly practice poses significant challenges for MFI control:

- Maintaining Physical Integrity: Repeated processing during edge-trim reclamation can lower molecular weight, reducing viscosity and increasing MFI. This leads to compromised mechanical properties, such as tensile strength and toughness.

- Optimizing Processing Conditions: Fluctuations in MFI complicate the setting of processing conditions, reducing efficiency and increasing rework and waste. Consistency across different production batches also becomes difficult to achieve.

- Preventing Unintended Cross-Linking: Multiple high-temperature processes during reclamation can trigger side reactions like cross-linking, creating ultra-high molecular weight polymers and irreversible crystalline points.

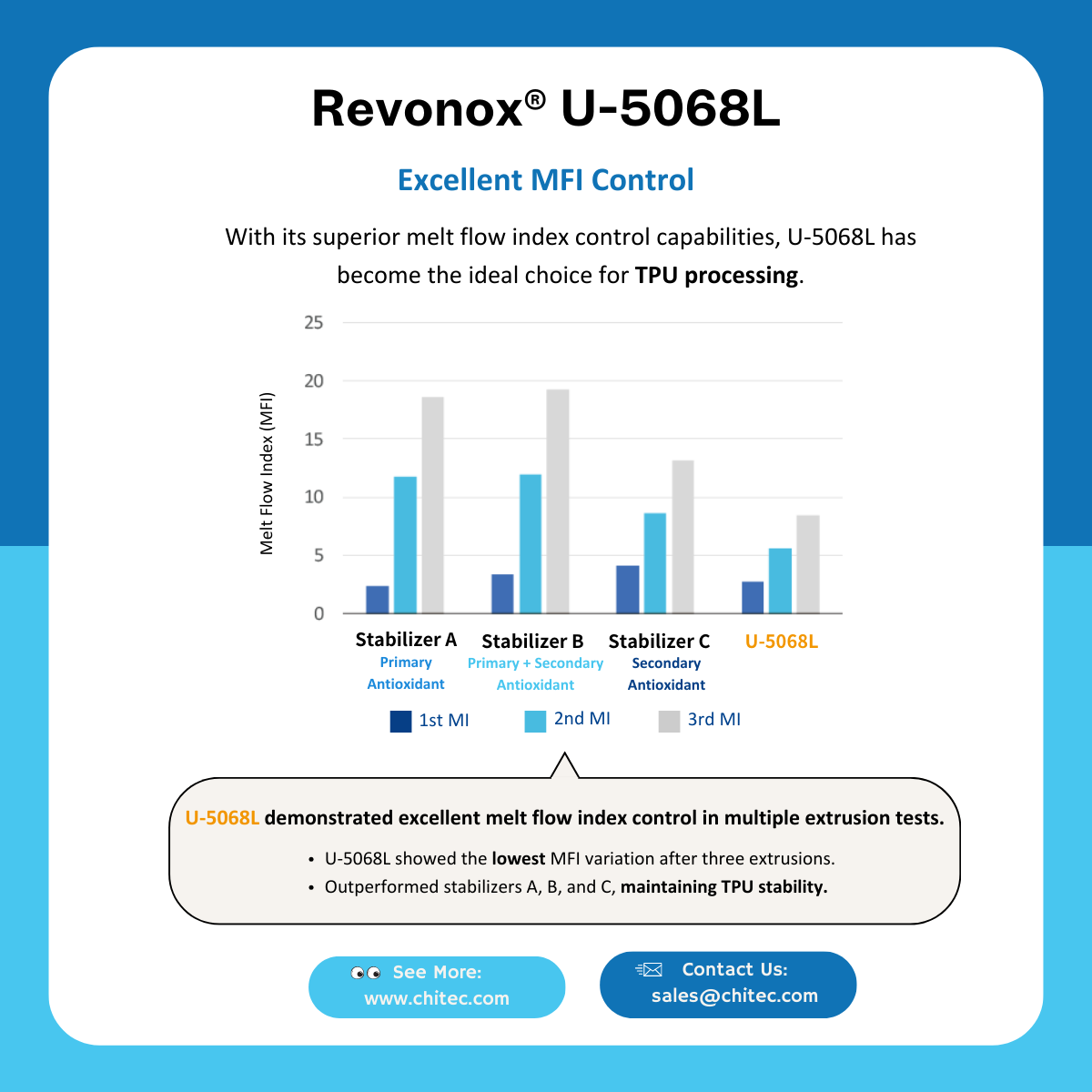

To demonstrate the superior performance of Revonox® U-5068L, we conducted extensive extrusion experiments. The results speak for themselves:

- Exceptional MFI Stability: Compared to other heat stabilizers (A, B, and C), Revonox® U-5068L showed the lowest MFI variation after three extrusions. This exceptional control ensures TPU stability throughout multiple processing cycles.

- Outperforming Competitors: While other stabilizers like product C (a phosphorus-based secondary antioxidant) also showed promise, they come with potential hydrolysis issues for polyester TPU. Revonox® U-5068L, on the other hand, excels without these drawbacks.

Revonox® U-5068L’s superior MFI control capabilities protect TPU’s physical properties during repeated thermal processing, reducing structural degradation and enhancing both processing performance and product quality. This makes Revonox® U-5068L the top choice for any high-performance TPU application.

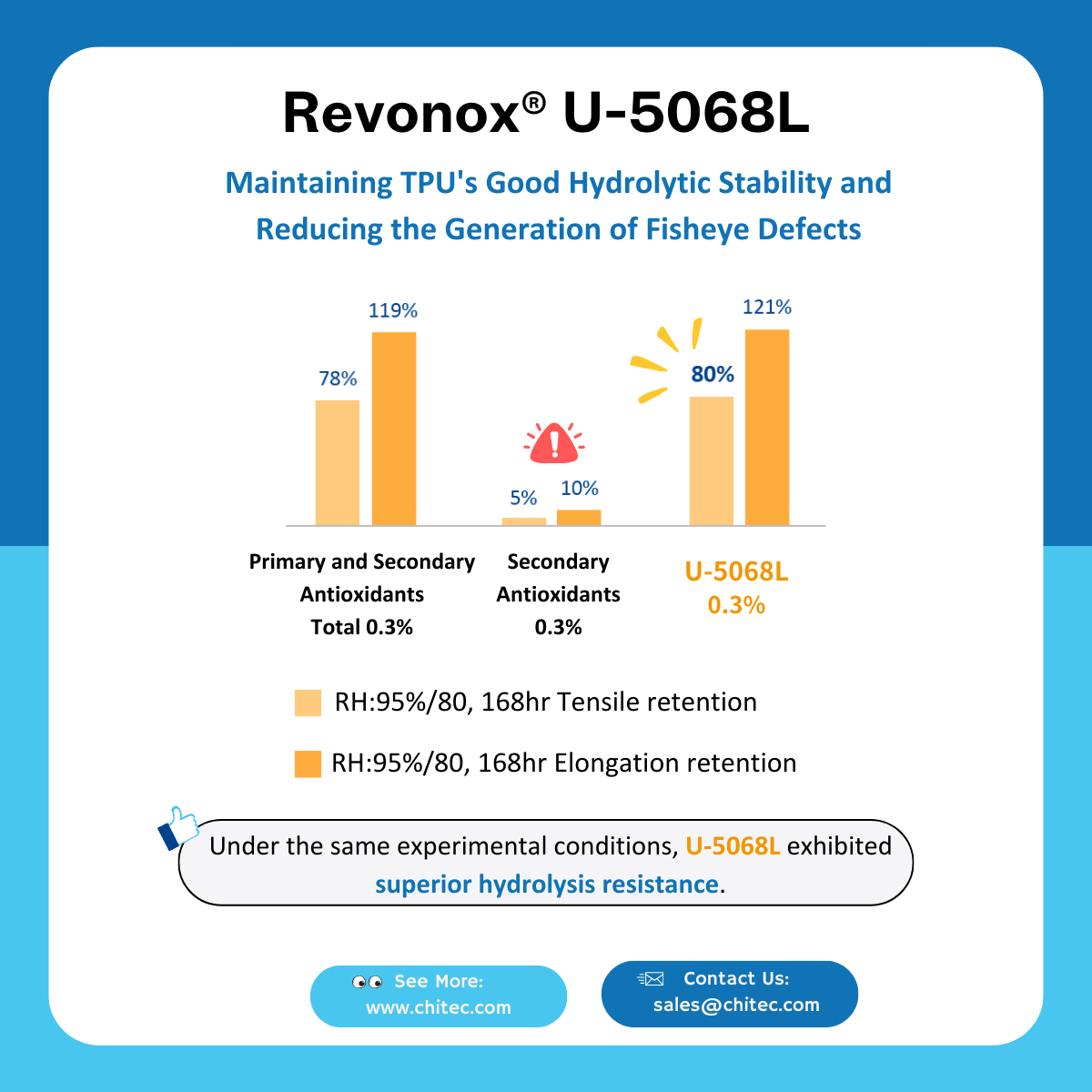

Maintaining Hydrolytic Resistance & Reducing Crystalline Points

The stability of hydrolysis resistance of thermoplastic polyurethane (TPU) materials is crucial for ensuring product durability. Revonox® U-5068L is a highly efficient and versatile TPU thermal stabilizer designed to maintain excellent color and physical properties without compromising TPU's good hydrolytic resistance. Additionally, U-5068L is one of the few thermal stabilizers on the market that can effectively inhibit the generation of crystalline points (fisheye defects) in TPU, which is of great industrial value in the production of TPU films thinner than 50 μm.

TPU polymers are prone to hydrolysis in acidic and water-rich environments, where the resulting acidic substances further act as catalysts, accelerating the hydrolysis reaction and damaging the molecular structure, making TPU brittle.

Research shows that while secondary phosphite antioxidants (such as phosphite esters) offer great color and processing stability, they absorb moisture and self-hydrolyze, producing phosphorous acid that catalyzes the hydrolysis of polyester-based TPU. From a consumer perspective, this results in sticky surfaces, cracking, and loss of material properties over time.

Although anti-hydrolysis agents are often used in formulations to address this issue, they increase cost. Revonox® U-5068L ensures excellent thermal stability without sacrificing TPU’s inherent hydrolytic resistance.

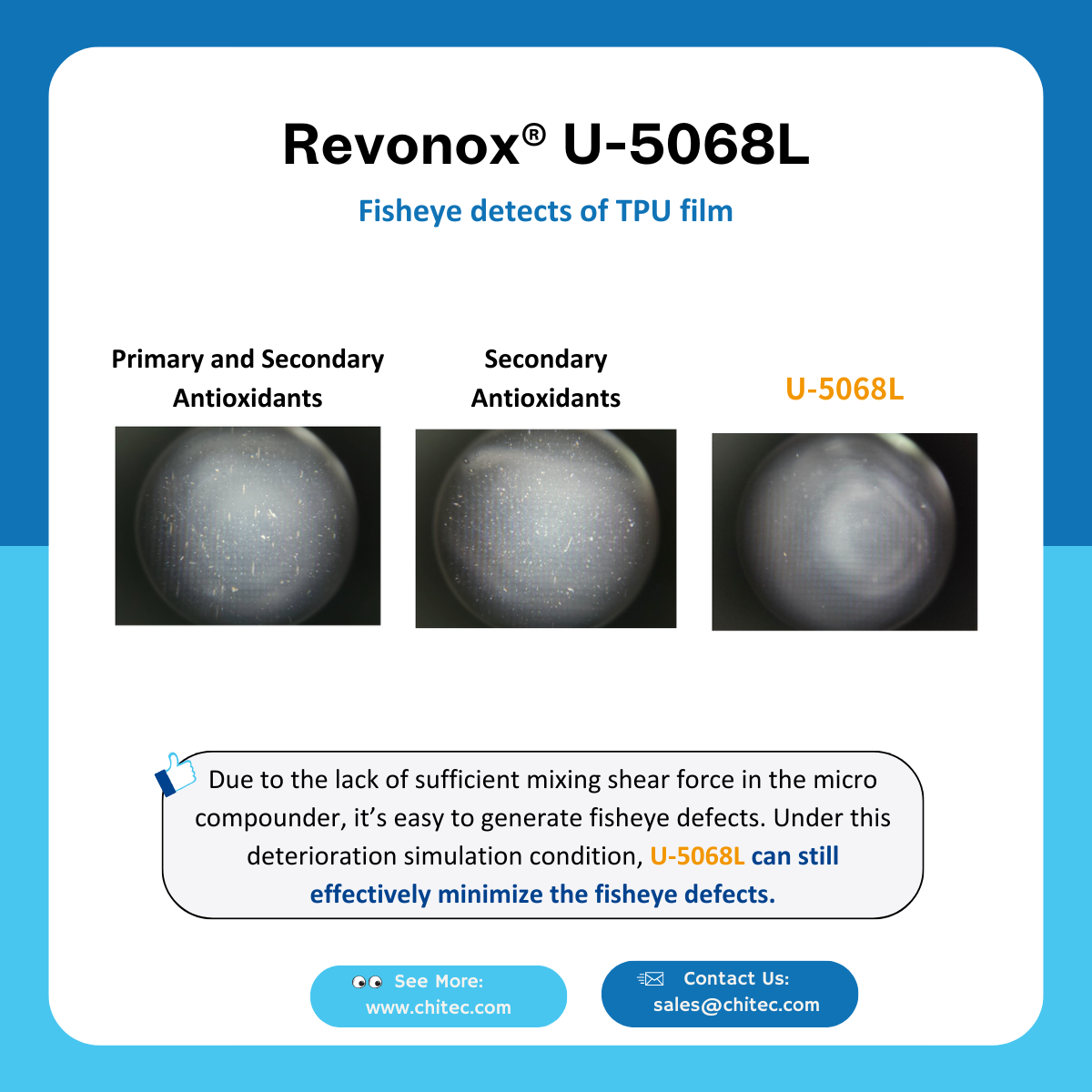

Crystalline points are a common technical challenge in TPU film production. These granular or arrowhead-shaped blemishes arise from side reactions during TPU synthesis that form ultra-high molecular weight polymers.

Revonox® U-5068L effectively inhibits these side reactions, significantly reducing the formation of crystalline points and ensuring consistent film quality—especially critical in demanding, high-end markets.

Revonox® U-5068L is a comprehensive TPU thermal stabilizer that delivers outstanding color and physical property retention, supports hydrolytic resistance, and prevents crystalline point formation—making it the top choice for high-performance TPU manufacturing.

Talk with our experts

Get formulation advice and technical support for integrating Revonox® U-5068L into your TPU systems.